Joe Justice + Peter Stevens: Certified Scrum Master for Management and Manufacturing

22-04-2013XM Principle 1: Optimize for change

03-06-2013In 2008, Joe Justice responded to a challenge from the X-Prize competition to create a road-legal 100mpg automobile. Despite having little time, hardly any budget, competition from over 100 well-funded competitors from companies and universities around the world, and changing requirements from the awards committee, his company’s WIKISPEED entry placed 10th in the Mainstream class. Joe not only created a great car, he also developed an Agile approach to creating physical products.

As a software developer, Joe was an “Agile native.” He had only worked with methods like Scrum and Extreme Programming, so his engineering practices drew heavily on his software experience. Today, WIKISPEED is selling prototypes, and the WIKISPEED approach to manufacturing is turning heads worldwide at companies like Boeing and John Deere. “Our technology is more sophisticated than yours, but your culture is light-years ahead of ours!”

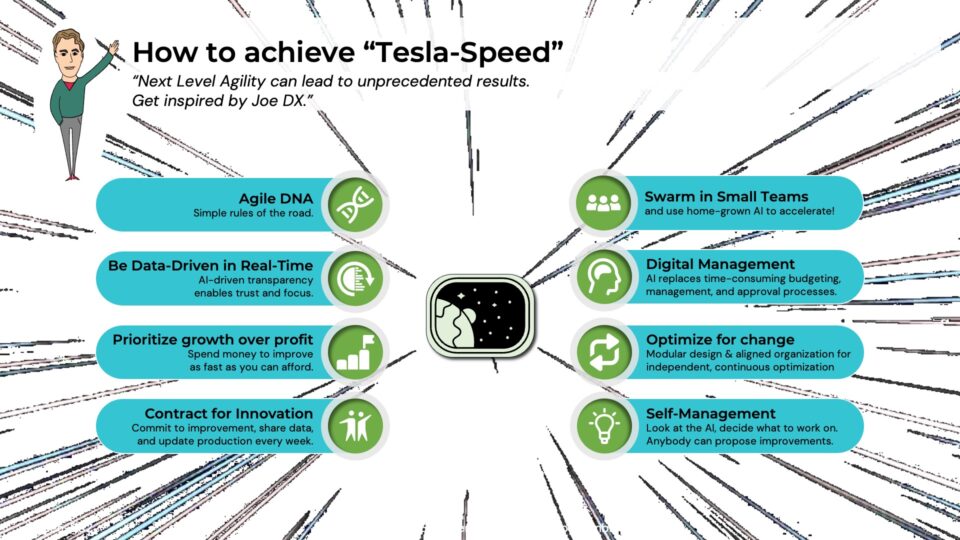

Joe calls his approach “Extreme Manufacturing.” XM emphasizes the ability to create products quickly and integrate changes rapidly into existing products. XM is collection of principles and patterns to help you create and adapt products quickly.

I had the honor of co-teaching a CSM + Extreme Manufacturing course with Joe last week, and with his encouragement, this series of articles seeks to refine, document and publish those principles:

- Optimize for change

- Object-Oriented, Modular Architecture

- Test Driven Development (Red, Green, Refactor)

- Contract-First Design

- Iterate the Design

- Agile Hardware Design Patterns

- Continuous Integration Development

- Continuously Deployed Development

- Scaling Patterns

- Partner Patterns

These principles and patterns do not represent the final wisdom on Agile manufacturing, but rather a work-in-progress, on the discovery of better ways to manufacture things.

I plan to publish an article on each of the 10 Principles of Extreme Manufacturing, every day for the next two weeks.

Let start: XM Principle 1: Optimize for change

2 Comments

Dear Peter, thank you for your inspirational post. I had the pleasure to meet Joe in Paris last summer. After our conversation I decided to write a case study on Wikispeed so that students and executives can discuss extreme manufactoring and agile principles around the world. The case is now available on the Harvard Business School website:

http://cb.hbsp.harvard.edu/cb/web/product_detail.seam;jsessionid=0196252AE73A18C52D6FAB1E45F1BD1C?E=4836621&R=ES1391-PDF-ENG&conversationId=646423

Happy to send you a copy and would love to get your feedback and comments.

Best

Martin

Hi Martin,

Sorry I didn't see this and post it sooner. I am somewhat overwhelmed with spam comments on this blog 🙁

Pity there is a paywall to your article. Does anybody actually make any money with these fees?

In any case, I would be very happy to review and discuss your article! Why don't you contact me so we can exchange email addresses?