Is it okay to change Scrum?

18-09-2023

Collective Intelligence Workshops

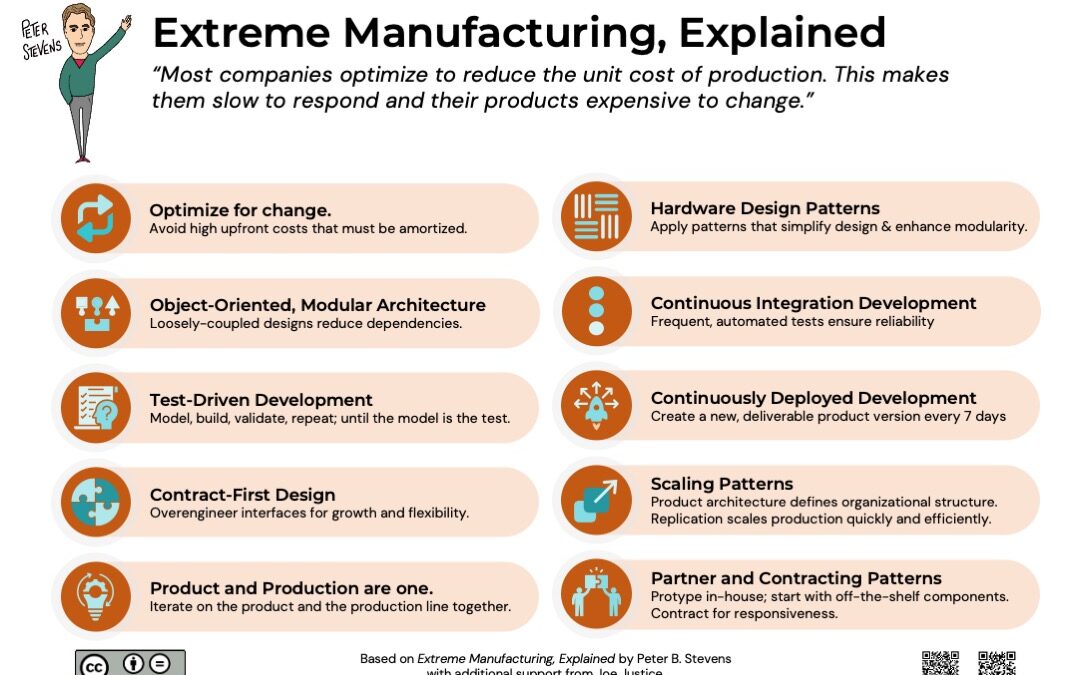

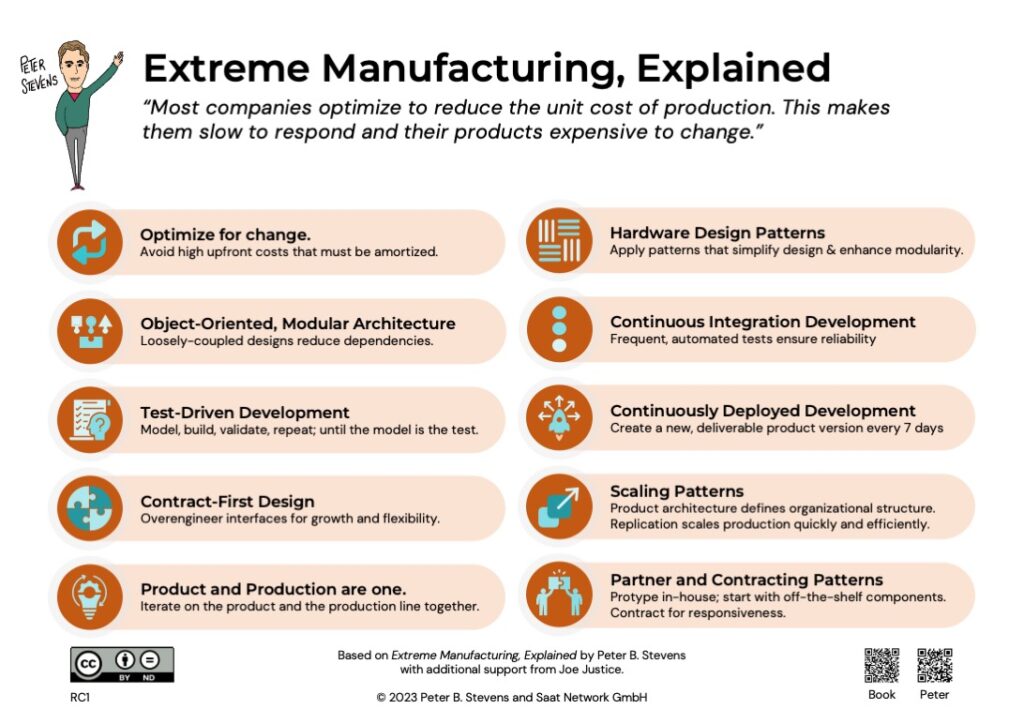

02-10-2023Are you struggling with slow product development cycles? The market’s rapid pace can leave your efforts behind. Here’s how Extreme Manufacturing can revolutionize your approach!

Extreme Manufacturing is a set of principles and patterns that were first pioneered by Joe Justice and project WIKISPEED back in the early 2010s. Today we see them very evident in places like Tesla, SpaceX, Bosch and John Deere and others. Here’s how it works:

- Optimize for Change: Shift your prime objective away from minimizing unit cost of production. High upfront costs must be amortized, so change is financially not possible. Instead, emphasize low cost of change, so implementing a new version is only marginally more effective than continuing with an existing version. This maximizes flexibility.

- Modular Architecture: Embrace an object-oriented, modular design. Loosely coupled components make adapting easier.

- Test-Driven Development: Create a model, build, validate, and iterate. The model evolves into the test. Over time, virtual tests replace expensive tests of physical versions of the product. This increases the likelihood of a successful results and lowers the cost of change.

- Contract-First Design: Define the main modules and their interfaces as contracts. Over-engineer the interfaces to ensure they can meet future needs. This reduces dependencies, makes improvement on either side of the interface easier, and keeps all your options open with minimal risk.

- Develop Product and Production Together: Combine product and production line development. You improve both as you iterate on the product.

- Hardware Design Patterns simplify the design and enhance modularity of the product.

- Continuous Integration: Frequent automated tests ensure your design works. SpaceX applies this approach to ensure the Falcon 9 will fly after each software upgrade.

- Continuously Deployed Development: Create a new product version at least once a week. You take a hard problem – change – and get good at solving it so it becomes a competitive advantage.

- Scaling Patterns: Follow Justices Law – the Inverse of Conway’s Law – to let product architecture shape the organizational structure. Like RAID (redundant arrays of inexpensive disks) enables high storage capacity by adding disks, agile manufacturing lines let you can scale your production for low incremental cost.

- Agile Contracting: Work with your suppliers to ensure responsiveness. Like you, they need to be able to deliver new versions of their components every seven days.

🔗 Elevate your product development with these Extreme Manufacturing principles. Which of these principles are you already applying? Share your thoughts!